Blasthole Design

Blasting is used to convert in-situ rock mass into a muckpile that has an appropriate fragment size distribution, shape and looseness, for extraction using the available excavation equipment. This must be achieved in such a way as to minimise the damage to the surrounding rock and avoid excessive flyrock, noise or vibration.

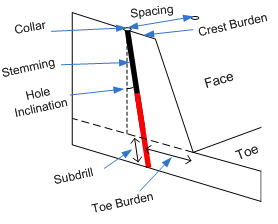

The rock targeted to be blasted is the burden in front of the blasthole. The blasthole is drilled a short distance (sub-drill) below the design floor (bench level) to ensure adequate breakage between blastholes on the same level. When a blast extends to the roof of a coal seam, the sub-drill wil be negative to separate the explosives from the coal seam.

The explosive is confined within the blasthole by broken rock placed above the charge (stemming). The basic objective of a blast design is to provide enough explosive in each blasthole to adequately fragment the volume of rock defined by the bench height and the crest and toe burden.

Established 'rules of thumb' can be used to determine the appropriate blast pattern, bench height, hole diameter, and the type and amount of explosives charge to be used in each hole.