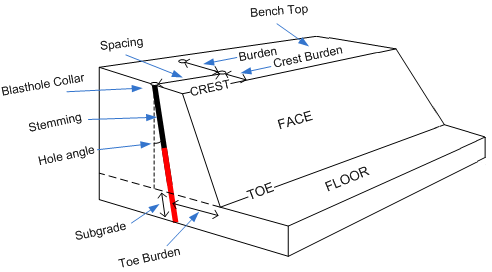

Burden and Spacing

Blasthole burden and spacing distances must be chosen to suit the factors listed below:

- rock mass (strength, geological structure and density)

- blasthole diameter (ie. the actual diameter, allowing for drill bit wear)

- overall geometry of the blast rock (eg, height, shape, and free faces)

- total "fragmentation" energy and "heave" energy of explosives

- the results required (ie. fragmentation, displacement, and muckpile looseness)

If the rock mass contains layers of strong and weak rock, the blasthole pattern must usually suit the material that is hardest to blast. In some situations, a combination of explosives may be used to effectively deal with this type of problem (for example, denser or more powerful explosives in the stronger rock).

The standard recommendation for blasthole burden is 20 to 35 blasthole diameters, but the "correct" figure can vary from 15 to 40 for different situations. Blasthole spacing usually ranges from 100% to 200% of the burden distance.

Typical burden and spacing values (mm) for bench blasting STRONG, MODERATE or WEAK rock types:

|

STRONG |

BURDEN SPACING |

1.0 1.2 |

1.1 1.4 |

1.5 1.8 |

1.8 2.1 |

2.1 2.4 |

2.3 2.6 |

2.5 2.9 |

2.7 3.1 |

|

MODERATE |

BURDEN SPACING |

1.5 1.8 |

1.8 2.1 |

2.1 2.4 |

2.4 2.7 |

2.7 3.1 |

3.0 3.5 |

3.3 3.8 |

3.7 4.2 |

|

WEAK |

BURDEN SPACING |

1.8 2.1 |

2.3 2.7 |

2.7 3.2 |

3.0 3.6 |

3.3 4.0 |

3.7 4.5 |

4.1 5.0 |

4.5 5.5 |

These figures are based on conventional bench blasting with high, open free faces, using loose-poured ANFO and millisecond delay firing. The appropriate burden and spacing can only ever be determined after carefully examining the rock mass and the after-effects of any previous blasting.

Rules of thumb for Burden and Spacing:

Burden

The Burden distance will generally lie between 20 to 35 times the hole diameter depending on the rock density and energy of the explosives used. A figure of 20 times can be used for very hard massive rocks, 27 to 28 for average rock, and 35 for softer or well jointed rock.

Occasionally in very easy to blast rock, a factor of more than 35 can be used.

B = (20 to 35) d

Where:

B = Burden in metres

d = Hole diameter in metres

For example, the hole diameter is 102mm and the rock type is average:

B = (20 to 35) HD (select 27 or 28 as average rock)

= 27 x 0.102m = 2.754m

= 2.7m (rounded down)

Spacing

The Spacing distance between blastholes is generally between 1 to 1.8 times the burden, with 1 used for very hard massive rock and 1.8 for very soft or well jointed rock.

A staggered drilling pattern is generally considered more efficient than a square or rectangular pattern. The use of a Spacing to Burden ration of 1.15 will give an equilateral triangular pattern which will provide the optimum energy distribution (in the horizontal plane) in difficult blasting situations.

For example, if the burden is 2.7m, what should the toe spacing be to provide an equilateral triangular pattern?

S = 1.15 x B

= 1.15 x 2.7m

= 3.105m

= 3.1m (rounded)