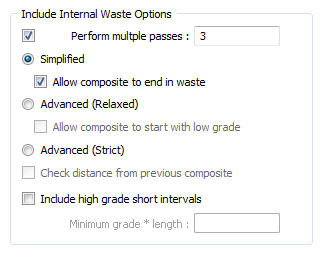

When INCLUDE INTERNAL WASTE is the chosen processing method, there are three rule sets for dealing with internal waste when creating composites by grade. Each of these rules have additional options that can be toggled on or off.

- Simplified

- Allow composite to end in waste

- Advanced (Relaxed)

- Allow composite to start with low grade

- Check distance from previous composite

- Advanced (Strict)

- Check distance from previous composite

Other options apply to all rules:

All Rules

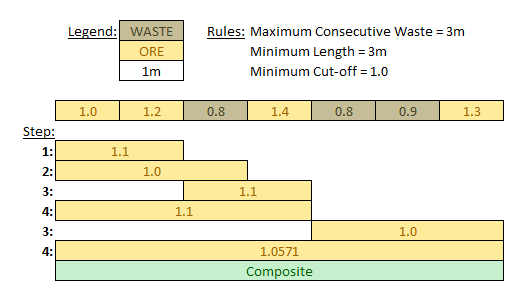

When dealing with internal waste, we move down a drillhole within the Interval file, monitoring the grade of each interval. If the interval’s grade is less than the trigger value then the interval is considered to be waste. If the interval’s grade is greater than or equal to the trigger value, then the interval is considered to be ore.

If an interval is in the same state as the previous interval, then these are considered to be part of the same ore or waste section. It is on the transition from one section to another (e.g. from ore to waste) that the rules from our specific rule sets are applied. On the transition from one interval to the next, we check that we do not exceed the maximum total and consecutive waste, the maximum gap, and the maximum composite length.

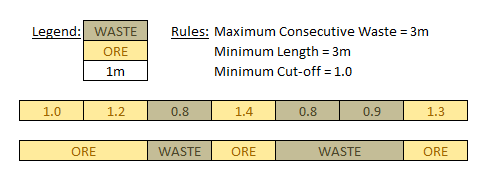

Figure 1: Defining the states of the intervals in a drillhole.

Step 1 of each rule set is to create the first ore section by ignoring any preceding waste intervals and detecting the transition from this ore section to a waste section. This always occurs on the very first transition from ore to waste in the current composite being built, the three rule sets implementations diverge from this point.

Include high grade short intervals

All rules have an option 'Include high grade short intervals' which requires a value to be defined with it. This option allows a final check before a potential composite is excluded for being below the minimum length. If the sum of the grade multiplied by the length for each interval is greater than the value supplied by the user, then this composite will be kept, as it is considered to be high grade.

The standard value for this field is the minimum grade multiplied by the minimum length.

Perform multiple passes

All rules also have an option 'Perform multiple passes' which will cause the algorithm to pass over the hole multiple times with the rule set. After the first pass, the compositing process will convert some waste to be considered as ore. Therefore on subsequent passes, some sections that failed due to exceeding the maximum waste rules will have the potential of succeeding.

If the number of passes is not specified, two passes are performed by default. Any positive integer value may be entered, including 1.

Simplified

The aim of the simplified rule set is to create the longest composite satisfying the rules, by adding waste-ore sections to an original ore section until the overall grade is as close to, but no less than, the final composite grade cutoff.

With the simplified rule set, the rules are applied on the transition from an ore section to a waste section. We add this waste-ore section to the first ore section or, on subsequent iterations, to the previous predicted composite if the overall grade of the composite does not drop below the cutoff as seen at Step 2 of Figures 2 & 3 below.

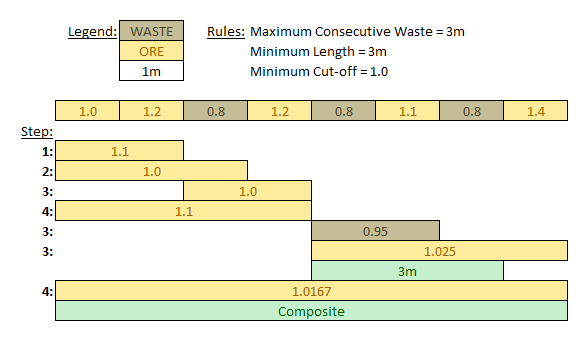

Figure 2: Applying the simplified rule set to the drillhole.

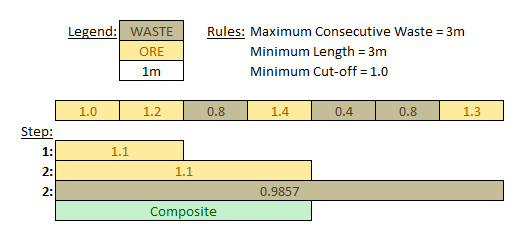

Figure 3: Another example of applying the simplified rule set.

Allow composite to end in waste

If a maximum length is defined, then an additional option ‘Allow composite to end in waste’ is available when the Simplified rule set is selected. If the current composite is at the maximum length and the compositing process is currently in waste, if the ‘Allow composite to end in waste’ option is off, then the end of the last ore section will be considered the end of the potential composites.

If the ‘Allow composite to end in waste’ option is on, then we will move the end of the potential composite to the current point within the waste, but only if the overall grade is greater than or equal to the final composite grade cutoff.

Advanced (Relaxed)

The aim of the relaxed rule set is to create a composite without adding a waste-ore section that is below the cutoff grade, as this is considered to be too diluting.

With the relaxed rule set, the rules are applied at both the transition from an ore section to a waste section, and from a waste section to an ore section. We apply rules to the transition from a waste section to an ore section if there is only a single ore section included in the composite (the single ore section does not include ore sections reclassified as waste).

Allow composite to start with low grade

At this transition (Step 2 of Figure 4 & 5) we know the first ore section and the first waste section, and check that the average grade is not less than the cutoff grade. If it is less than the cutoff grade it is considered to be diluting. If ‘Allow composite to start with low grade’ is off, then stop compositing, otherwise this ore-waste section will be flagged to be potentially excluded. Once the composite has been finalised there is a final check to see if the composite would be acceptable after excluding the diluting first ore-waste section, in which case the first ore section is considered as a composite on its own and the process begins again from the second ore section.

On the transition from an ore section to a waste section (Step 3 of Figure 4 & 5) we have the waste-ore section by combining this ore section with the preceding waste section. We consider the average grade of this waste-ore section and if it is below the cutoff grade, then the waste-ore section is considered diluting, otherwise it is added to the composite.

If the waste-ore section is considered diluting, rather than ending the composite at this point, we reclassify the current ore section to a waste section and resume as though we never hit an ore section (Figure 5). This ore section will be included in consecutive waste calculations but not in maximum total waste calculations. It will also not be considered as an ore section when considering the number of ore sections that have been added to the composite. Therefore, if the length of the waste-ore-waste section where the central ore section was reclassified as waste, is greater than the maximum consecutive waste, then we will stop expanding the current composite. If it was not greater than this limit then the next waste-ore section will have the entire waste-ore-waste section, where the central ore section was reclassified as waste, considered as its waste section.

If the waste-ore section is acceptable then we check that adding this section to the overall composite doesn’t bring the average grade below the cutoff grade (Step 4). If this is acceptable, we mark this as the last known end of composite and continue trying to add the next waste-ore section.

Check distance from previous composite

Usually the algorithm continues from the first ore section after the end of the previous potential composite. If ‘Check distance from previous composite’ is off, then the algorithm continues from the last processed record, where the waste rules were broken. This process is repeated until we have processed the entire current composite.

If ‘Check distance from previous composite’ is on, then the resulting potential composite list will be further modified. We compare the distance between acceptable composites in the list and if the distance is less than the maximum consecutive waste we move the end of the first composite to the previous last known good positions along it, until the distance between the composites is greater than the maximum consecutive waste, or we are left with just the first ore section of the potential composite.

The algorithm is repeated a second time, working through the current composite in the other direction, which will generate a second potential composite list. We then compare the grade sum of each list (only using the acceptable composites in the list) and use the resulting composites from the list with the highest grade sum.

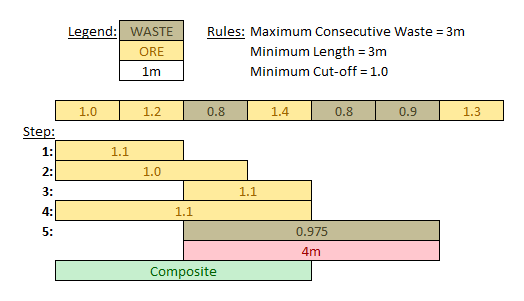

Figure 4: Applying the relaxed advanced rule set to the drillhole.

Figure 5: Another example of applying the relaxed advanced rule set.

Advanced (Strict)

The aim of the strict rule set is to create a composite with no diluting sections whatsoever. That is, sections on either end of the composite should never be below the cutoff grade, and no internal waste-anything-waste sections can be below the cutoff and exceed the maximum consecutive waste.

The strict rule set will first create composites using the Advanced (Relaxed) rule set with ‘Allow composite to start with low grade’ set to false.

Then on the final pass over the hole it will apply specialised rules to the resulting composites.

The strict algorithm will go through the potential composite and check a waste-ore section with the next waste section, if the resulting waste-ore-waste section is below the cutoff then the entire section will be reclassified to waste and be checked to ensure that the resulting waste section does not break any of the waste rules. The resulting waste section will be checked with the previous waste-ore section and repeat the above checks until there are no more waste-ore sections or waste-ore-waste sections below the cutoff grade. If the waste rules are broken then we add the acceptable portion of the current composite to a potential composite list and then continue performing the strict algorithm on the remaining portion of the current composite.

Check distance from previous composite

Usually the algorithm continues from the first ore section after the end of the previous potential composite. If ‘Check distance from previous composite’ is off, then the algorithm continues from the last processed record, where the waste rules were broken. This process is repeated until we have processed the entire current composite.

If ‘Check distance from previous composite’ is on, then the resulting potential composite list will be further modified. We compare the distance between acceptable composites in the list and if the distance is less than the maximum consecutive waste we move the end of the first composite to the previous last known good positions along it, until the distance between the composites is greater than the maximum consecutive waste, or we are left with just the first ore section of the potential composite.

The algorithm is repeated a second time, working through the current composite in the other direction, which will generate a second potential composite list. We then compare the grade sum of each list (only using the acceptable composites in the list) and use the resulting composites from the list with the highest grade sum.

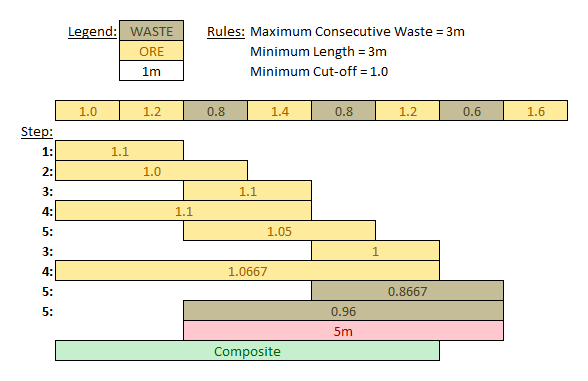

Figure 6: Applying the strict advanced rule set to a composite.

Figure 7: Another example of applying the strict advanced rule set to a composite.